Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

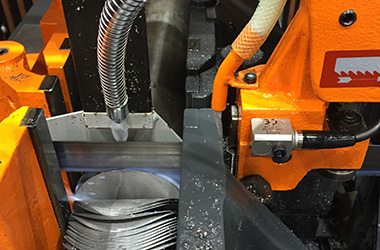

COSEN has long been known for manufacturing high quality, professional sawing machines. By always putting the customer first, they have become one of the world’s largest band saw manufacturers. The company has sought new and innovative ways to help their customers reduce waste. COSEN wanted to utilize the latest technology to optimize the life span of their saw blades. There was no way to know when saw blades needed to be changed, resulting in either bad cuts or premature replacement of blades.

Digiducer on COSEN Saw

In 2013, COSEN launched MechaLOGIX, a software brand aimed at allowing customers to perform predictive maintenance on their saws. However, they still needed a way to collect data on the saw blades so they teamed up with the Center for Intelligent Maintenance Systems (IMS) to create a simple, yet innovative solution centered on Digiducer’s vibration sensing technology. COSEN mounted a Digiducer® USB accelerometer on their band saw and connected the Digiducer directly to the on-board computer. They were then able to measure the vibration levels generated during each cut. This information made it easy to monitor the health of the saw blade and determine the best time to make a change.

SawLOGIX App Dashboard

By using the Digiducer, COSEN was able to quickly turn their standard band saw into a cutting edge, smart machine. With the MechaLOGIX mobile app, customers can now monitor all of their COSEN saws from their phones. With the app customers can make informed, real-time maintenance decisions, taking the guesswork out of changing blades. With the help of Digiducer, COSEN has revolutionized the way customers interact with their saws, saving both time and money.

SawLOGIX App Blade Health Graph